.

This guide is based on my own greenhouse, which I built and have used for four growing seasons.

Standing in my vegetable garden on a rainy summer day, watching my tomato plants struggle under these humid conditions, I dreamed of a greenhouse—a warm sanctuary where peppers could ripen, tomatoes could climb to the ceiling, and the growing season wouldn’t end with the first frost.

What I didn’t realise was that this dream would lead me on a journey from browsing expensive catalogues to hammering in my own ground sleeves, learning how to build a DIY wooden greenhouse from scratch – something far better than anything I could have bought.

Here’s a quick summary of what building this greenhouse involved.

Quick Overview

Building a Greenhouse from Scratch

| Greenhouse type: | DIY wooden greenhouse with plastic covering |

| Foundation: | Ground sleeves driven into soil (no concrete base) |

| Total cost: | ~€1,300 in materials |

| Build time: | Several weekends, weather-dependent |

| Skill level: | Beginner-friendly with basic DIY skills |

| Best suited: | Gardeners wanting a low-cost, non-permanent greenhouse |

Research

As I said, I first looked for ready-made options. There were, of course, several varieties of greenhouse kits, but a greenhouse of the size I wanted (about 10 x 3 metres) was nearly impossible to find, and when I finally found one, it was definitely not within my budget!

Another problem was that all these greenhouse kits had to be fixed onto a solid concrete base. As I do not own my garden but have rented it, I am neither allowed to plant deep-rooted bushes or trees nor set up anything permanent. Like a solid concrete base. But how to make sure that the greenhouse would be safely anchored without a base? So I googled DIY greenhouse construction without a permanent foundation.

There were, of course, greenhouse tunnels that had a frame made of curved PVC tubes that were stuck into the earth. However, as we have severe storms around here, especially during autumn, I was afraid that one of those would lift the greenhouse right out of the ground and send it flying through a neighbour’s window. So, a greenhouse tunnel with a frame of PVC tubes was certainly not an option either.

It was my dad, finally, who suggested building a greenhouse from scratch with wood and using ground sleeves as point foundations. I was sceptical at first–would simple ground sleeves really be enough to keep a greenhouse safely anchored? Four years later, I can tell you: this has worked reliably for me over four seasons!

Planning your greenhouse: What you need to build a greenhouse from scratch

But how to build a greenhouse without concrete foundations? I’m not all thumbs when it comes to handcrafting, but I haven’t had much experience either. Well, the first step is:

Drawing your greenhouse plan

By the way: Planning is an ideal task for winter, when there are only a few things to do in the garden (for more details, read on here about January garden tasks).

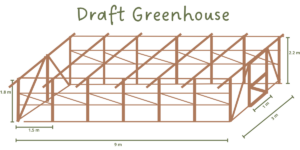

First, I drew a rough plan of the greenhouse and talked it over with my dad and an acquaintance who is an experienced carpenter. I had to adjust some things and refine the details, but in the end, I was good to go. Here is my draft. Feel free to use and adapt it if you’re planning your own greenhouse project.

I set the greenhouse behind the vegetable garden, facing south for optimal light yield. The south side is 1,8 metres (3.3 feet) high and 9 metres (30 feet) long, and the north side has a height of 2,2 metres (6.5 feet). Those two long walls are 3 metres (10 feet) apart, so I have gained 27 square metres (300 square feet) of additional gardening space (9 x 3 metres / 30 x 10 feet).

Beginner note:

You don’t need a perfectly scaled drawing or technical software. A hand-drawn sketch with measurements is enough—as long as you know where every beam and opening will go.Advanced note:

If you’re comfortable with it, sketching your plan to scale or using simple CAD software can help you pre-calculate angles and material lengths more precisely.

Choosing your location

When you’re planning a greenhouse in your garden, you’ll want to put it in direct sunlight while making sure that it doesn’t cast a shadow on already existing beds.

In my case, it was obvious that I wanted the greenhouse to go behind the vegetable garden, that is, at the north side. That way, it wouldn’t throw a shadow on the existing garden while at the same time protecting it from harsh north winds.

Before you start: What you need to know

Now that you have your design planned out, let’s talk about the practical side: what this will actually cost, how long it takes, and what you’ll need to get started.

How much will this cost? (And is it worth it?)

Before we dive into the details of building a greenhouse from scratch, let’s talk about costs. I’m sure you’re dying to know if the whole procedure is worth the trouble.

Well, the ready-made options I found online, in catalogues, and at hardware stores ranged from € 5,000 to € 23,000. Nothing I could or would remotely ever pay for a greenhouse. For that amount of money, I could buy organic vegetables for the rest of our lives. Of course, prices may vary in your region, but I doubt you’ll find something cheap.

The total cost to build this greenhouse was €1.310.

Here’s a list of everything I needed and what it cost:

| Item | Details | Cost |

|---|---|---|

| Ground sleeves | 16 sleeves, 90cm length, 7x7cm top | 100 € |

| Wood | Beams, boards and battens, cut to size at the sawmill | 500 € |

| Screws | Various sizes for construction | 200 € |

| Hinges and hardware | 24 window hinges, 3 door hinges, 1 door bolt | 80 € |

| Heavy-duty tarp | Grid-reinforced greenhouse film | 250 € |

| Gutter system | Brackets, tubes, end pieces | 100 € |

| Water container | 1000-liter capacity (secondhand) | 80 € |

| Total | 1.310 € |

Ready to start planning your own greenhouse? Get my weekly gardening tips delivered to your inbox!

Join the Seasonal Simple Life Community!

Seasonal inspiration for your garden, kitchen, and home—delivered with care every week.

Depending on your region, these costs may vary as well, of course, but I’m pretty sure it’ll still be way less than a ready-made greenhouse.

For €1310 and several weekends of work, I gained 27 square metres of growing space that a comparable ready-made greenhouse would have cost at least € 5.500, plus installation—if I could even find one this size.

Beginner note:

If this is your first large DIY project, expect it to take longer than planned—and that’s completely normal. Build in extra time so the process stays enjoyable.Advanced note:

With pre-cut lumber, power tools, and a second person, you could reduce the build time by several weekends.

How long does it take to build a greenhouse from scratch?

Bear in mind that I worked mostly alone and on weekends when the weather permitted. With a helper, you could cut this time significantly. The key is not to rush—take time to ensure everything is level and secure.

| Description | Time frame |

|---|---|

| Planning and design | 2 weeks |

| Gathering materials | 1 week |

| Setting sleeves and frame | 2 weekends |

| Installing windows and tarp | 2 weekends |

| Finishing touches | 1 weekend |

| Total | About 6 - 7 weekends, spread over two months |

What tools do you need?

Must-have tools

- Spirit level

- Hammer or mallet

- Electric drill with bits – you can borrow one if your site has electricity

- Saw (hand saw works, electric is faster)

- Measuring tape (at least 5 meters)

- Folding rule

- String and stakes for marking

- Sharp knife

Nice-to-have tools

- Screw clamps

- Spade

- Planer or drawknife

Beginner note:

You don’t need professional-grade tools. I built most of this greenhouse with basic, borrowed equipment and hand tools.Advanced note:

Access to a table saw, impact driver, and laser level would speed things up considerably, but isn’t required.

Helpful skills

- Basic measuring and levelling

- Sawing in a straight line

- Using a drill

- Patience and problem-solving!

Don’t let this list intimidate you. I had never built anything this large before, and if I could learn as I went, so can you. The trick is just not give up.

When should you build?

I started building my greenhouse mid-March, but in hindsight, it would have been better to do it in the autumn of the preceding year.

Had I done so, I would have had more time to build the house–I got really stressed at one point, thinking that I’d never finish this project in time to really grow something in it that year.

Also, the soil I’d put into the greenhouse would have had time to settle before I put the plants in.

However, depending on your growth zone, your skills and experience with projects of this kind and if you have any help, late winter/early spring can be just fine to start building a greenhouse.

How to build a greenhouse from scratch

Step 1: Measuring and setting up a string frame

By the end of this step, you’ll have made a string frame for your DIY greenhouse.

First, I measured out the space behind the vegetable garden where I wanted to build my greenhouse and marked it with strings. I’m glad my dad helped me with that. If you (like me) have never done this before: don’t worry. Here’s a step-by-step guide on how to set up a string frame:

Marking your first corner

When you have decided where to put your greenhouse, you hammer a wooden (or metal) stake into the ground to mark a corner of your future greenhouse. Ensure the stake extends at least 20 cm (8 inches) above the ground for string attachment.

Creating the rectangle

Next, you measure out the small side (in my case, 3 metres / 10 feet) and hammer in a second stake. Connect these two stakes with a string. You then measure out the long side from one of the two stakes (here: 9 metres / 30 feet) and hammer in a third stake. Again, connect this stake with the first one.

Ensuring perfect squares with the diagonal method

Beginner note:

If this step feels confusing, take your time. Getting the base square makes everything else easier later—and fixing mistakes now is far simpler than correcting them later.Advanced note:

If your site isn’t perfectly flat, you can still square the frame—just focus on accurate horizontal measurements rather than ground level at this stage.

Now comes the coolest part: measure the diagonal length from the second to the third stake and make a note of the length. If, like in my case, you want to build a large greenhouse, you can do that with the help of a string that you attach to the second stake and pull it to the third one. Otherwise, you just use a folding rule. Mark the spot on the string where it touches the stake and measure it. Now you measure from the first stake to a (at that point imaginary) fourth stake until you have the same diagonal length as measured before between stakes two and three. Hammer in the stake and connect the last side with the string.

Step 2: Setting up the frame

By the end of this step, you’ll have

- set the ground sleeves

- pillar beams securely bolted

- a stable base frame including windows and a door

Setting the ground sleeves

Beginner note:

Ground sleeves are very forgiving. Small inaccuracies can be compensated for later when you attach the beams—don’t aim for perfection, aim for consistency.Advanced note:

In very loose or sandy soil, you may want to set sleeves slightly deeper or compact the soil around them with gravel for extra stability.

With the string frame in place, I started to hammer in the ground sleeves for greenhouse foundation, one on each corner and then one every 1,5 metres (3.5 feet) at the long sides. I used sleeves with a length of 90 cm (3 feet) and a 7×7 cm (2.75 x 2.75 inch) base on the top.

At the front of my future greenhouse, i.e. the short side facing east, I additionally added two sleeves where the doorframe would be. All in all, I used 16 ground sleeves (7 on each long side and two for the door frame).

All sleeves must be at exactly the same height. To ensure that, I used a plank, put it across two sleeves and measured with a spirit level. Since the area I built my greenhouse on isn’t level, I had to compensate. Some sleeves needed to be hammered deeper into the earth, while others stood higher—all carefully adjusted so the tops were perfectly level with each other.

I had to decide what my reference point for height was. Naturally, I took the deepest point in my greenhouse area where I let the sleeve stand out 20 cm (8 inches) above ground. The other sleeves were adjusted accordingly. That meant that while the reference sleeves stood out 20 cm (8 inches), some had to go 10 cm (4 inches) into the ground. There, I shovelled away the earth and hammered the sleeve into the right height. After every sleeve, check that it is level with the others.

Erecting the wooden beams

Beginner note:

If planing beams by eye feels intimidating, remove small amounts of wood at a time and test the fit often—you can always take more off, but you can’t put it back.Advanced note:

A thickness planer or belt sander makes this step faster and ensures consistent beam dimensions.

At my dad’s workshop, I sawed 8×8 cm (3×3 inches) wooden beams to the right length, which I determined with good old Pythagoras. I added an extra 15 cm (6 inches), though, as I wanted the beams to protrude over the south edge.

This was necessary, as I intended to fix a gutter on this side. In the end, I had 7 beams with 1,8 metres / 6 feet (south side) and 7 with 2,2 metres / 7 feet (north side), all with an angle of 13 ° at the upper side. The two beams for the doorframe were adjusted later.

To fit the wooden beams into the sleeves, I had to plane 0.5 cm / 0.2 inches on each side of the lower 10 cm (4 inches) of the beams. Since my 8×8 cm (3×3 inches) beams were slightly larger than the 7×7 cm (2.5 x 2.5 inches) sleeves, I planed them by eye until they fit snugly.

After fitting the beams into the sleeves, I drilled holes into them through the pre-made holes in the sleeves and stuck 8 cm (3 inches) carriage bolts into them. Lastly, I screwed them tightly into the sleeves using the carriage bolts and nuts.

Constructing the wooden greenhouse frame

Once the pillars were set, I started to build the wooden greenhouse framework for which I used boards that were 2,5 cm (1 inch) thick, about 20 cm (8 inches) broad and 4 – 5 metres (12 – 15 feet) long. I fixed the first board with a screw clamp across the bottom of the front corner pillar, starting at the south side.

Then I marked where it hit the last pillar it could reach (in this case, the third), took it off and sawed along the mark. My garden plot has no electricity connection, so everything had to be done by hand—a workout I hadn’t quite anticipated when I started this project!

After fixing it again with two screw clamps, I screwed the board to the pillars. In that way, I did all the bottom boards around the greenhouse and afterwards started screwing boards to the upper side of the pillars. I just had to remember that no bottom board was needed where the door should be built.

Adding windows

Next, I installed the frames for the windows that I wanted to build into the sections on the south and north sides. For this purpose, I took wooden battens (5 cm x 2,5 cm / 2 x 1 inches), measured the distance between two beams, sawed them to the measured length and screwed them in between the beams. For each window, I needed an upper and a bottom batten to complete the frame.

Window frames

Beginner note:

Slight variations in window size are perfectly fine. What matters is that each window fits its own opening, not that all windows are identical.Advanced note:

If you want tighter seals, you can add weatherstripping or overlap battens once the tarp is installed.

Now the windows had to be built. This was the same as building the window frames, but with additional sidebars. I measured out every section and sawed the battens according to measurement. I’m no carpenter, so the measurements varied a bit from section to section, so it made more sense to measure each section individually and saw the battens accordingly.

When the windows were ready, I fixed them into the frames with hinges at the lower part, two on each window, making sure that they opened to the outside of the greenhouse. I can’t tell you the delight I felt when I opened my first (empty) window, and it worked! In the end, I had 12 windows, six on the south and six on the north side, and it was time to tackle the ceiling.

My first completed window frame—empty, but perfect!

Tip: Always double-check that the windows open outward fully to allow ventilation.

Ceiling beams

Next, I laid beams of 3,15 m (10.3 feet) across the upright beams in a north-south direction so that they ended at the north side at the edge of the pillars and overhung on the south side by approximately 10 cm (4 inches). I screwed the ceiling beams onto the pillars and additionally fastened them with metal angles.

All, except the last one on the front. I only laid this beam onto the pillars, inserted the remaining two beams into the sleeves where the doorframe would be, and marked the height at which I had to saw so they would fit. I didn’t want to take the risk of calculating the height (I was never good at maths), so that seemed the best and easiest way to do it.

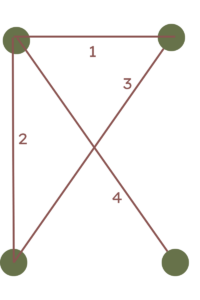

As the framework needed stability, I screwed boards diagonally across the backside and the fields left and right of the door frame. I also installed diagonal boards from each pillar beam to the adjacent ceiling beam. That done, stability had improved A LOT!

Beginner note:

Diagonal bracing may not look pretty, but it’s one of the most important elements for long-term stability—especially in windy regions.Advanced note:

Metal cross-bracing or tension cables can be used instead of wooden braces for a cleaner look.

Reinforcing the ceiling

The wooden beams on top are adjusted in a north-south direction. To make sure the tarp wouldn’t hang loosely and form sags when it was raining, I inserted boards between the beams’ sections. I started with the highest, i.e. the north side and screwed the boards on with angles so that they levelled with the top of the beams.

I did three boards per section, one on the north side, one in the middle and one on the south side, ending with the beams’ edges.

Building the door

Now, I had to build the door: I made a frame out of boards and stabilised it with a horizontal board in the middle and diagonal boards on the upper and lower sections. I then fixed it to the left pillar with hinges that were larger and thus more stable than the window hinges.

When that door swung smoothly on its hinges for the first time, I may have done a little victory dance. (Okay, definitely did a victory dance.)

Step 3: Covering

At the end of this step, you’ll have

- covered all sides of the greenhouse with tarp

- closed the ceiling

- secured the tarp in the soil

- cut open all windows and the door

Research on greenhouse covering

The last step now was to cover the whole DIY greenhouse frame with greenhouse film. I had done a lot of research in advance, comparing different possibilities like plastic twin-wall sheets, plexiglass, real glass and different greenhouse films.

The twin-wall sheets and plexiglass I dismissed pretty soon, as they would have been too expensive. The same went for real glass, which had the additional disadvantage of heating the greenhouse too much, so that shading would have been necessary–which would have cost even more.

Film it was then. Here, too, there are multiple possibilities. In the end, I opted for this heavy-duty tarp, which, due to its grid, is very stable and also thick enough to last several years (the manufacturer guarantees 3 – 5 years, but I think it may last a good deal longer. Time will show.)

Update (2025): After three years, the ceiling tarp developed holes in it, forcing me to replace it.

Covering the greenhouse sides

Beginner note:

This step is much easier with two people. If you’re working alone, clamps are your best friend—use more than you think you’ll need.Advanced note:

For long-term durability, sandwich the tarp between wooden battens and the frame rather than relying on screws alone.

Adjusting the heavy-duty tarp was the hardest part of this whole project, as it lives up to its name and is very heavy. However, with the help of several clamps (and after a bit of swearing and sweating), the first edge was tightly screwed to the corner beam of the east side using plumbing screws.

How to fix the tarp

Plumbing screws are metal screws with a rubber seal washer. That means that they have a larger contact area than without the washer, making sure that the film doesn’t tear out.

Update (2025): Despite the plumbing screws, the tarp was partly torn out when I replaced it after three years. This time, I fixed the tarp with boards on the framework.

Now, I pulled it to the next pillar and screwed it on, making sure that it was tightly stretched. Additionally, I fixed screws along the upper and lower boards and around the window frames, clinging them firmly to the wood. I started at the back wall and worked my way around the entire house. I made sure that the film levelled up at the upper side of the greenhouse and overlapped at the lower side.

Opening up the door

To enter the greenhouse, I used a sharp knife to cut a slit between the door and the doorframe. Next, I screwed a door latch onto the door and its counterpart onto the frame—and just like that, I could open it! It was a great moment entering “my house” for the first time!

Covering the greenhouse ceiling

Beginner note:

Wind stress adds up over time. Even if the tarp looks secure at first, reinforcing it now can save you from repairs later.Advanced note:

UV-resistant greenhouse film with reinforced edges lasts significantly longer than generic tarps, especially on roofs.

To get the ceiling covered, I first unfolded the tarp to its full size and then rolled it lengthwise. I then lifted it onto the ceiling and started to screw it onto the east beam. (Honestly, I don’t remember how I got that heavy foil onto the ceiling all by myself, but I’m pretty sure that some swearing was involved.)

I then unrolled the film inch by inch, using a lot of plumbing screws to screw it onto the beams and boards. I took a screw every 10 – 15 cm, in short: a lot! But I was (and still am a bit) scared that the wind would rip off the film and tear the whole greenhouse apart, and so I decided that in this case, more is more.

Update (2025): It turned out that my fears were justified– the tarp had ripped off the boards when I replaced it after three years. To prevent that, I additionally fixed the tarp with boards on the wooden framework.

Opening up the windows and digging in the tarp

The whole house was covered now, and I opened the windows by cutting around between their edges and the frame with a knife, just like before when I opened the door. To keep the windows from falling open, I took some wooden scraps, leftover pieces from the battens I’d sawed earlier, and hammered them not too tightly onto the upper frame so that I could turn them and use them as a latch.

The last step on this building journey was to dig the overlapping tarp into the soil. I used a spade to dig slits into the earth, stretched the tarp and burrowed it tightly by firmly pressing the soil with my feet.

Step 4: Final touches

Fixing the gutter

As a last step, I fixed a gutter to the south side of the greenhouse to collect the rainwater from the roof. I had bought several gutter brackets that I screwed onto the upper boards of the greenhouse frame, one bracket per metre.

As you need a slight slope to one side to which the rainwater will be flowing, I fixed the brackets in a descending line from west to east. That means I started with the first bracket on the west side, screwed it almost at the top of the board and gradually lowered the brackets so that the last on the east side was about 10 cm lower.

Then I stuck the gutter tubes together and inserted them into the brackets. I closed both gutter sides with end pieces. About one metre from the east side, I inserted a tube into the gutter that leads the water downward into a 1000-litre water container that I bought from eBay. Finally, with the gutter in place, I could collect rainwater efficiently—an eco-friendly bonus!

Prepare for planting

Beginner note:

Letting the soil settle for a few weeks before planting improves water retention and root stability.Advanced note:

Installing drip irrigation or soaker hoses before planting is much easier than retrofitting later.

With the greenhouse complete, it was time to prepare the beds. For this, I used the same method as with my garden: I laid out cartons, put some leftover manure I still had from the previous year and ordered some good humus. To determine how much soil you need, measure your planting area (excluding paths) and multiply by 0.15 m (0.5 feet) to raise your beds 15 cm (6 inches) high.

This is the soil for my greenhouse—it took me two hours to distribute it all!

This shows the massive pile I had to move.

Laying out cardboard for bed preparation

Distributing the manure evenly

Ready for planting!

Finally, I was ready to plant my tomato, pepper and cucumber plants in the greenhouse, which had grown very large already!

What I’d do differently next time

Beginner & Advanced takeaway:

If you only take one thing from this section, let it be this: start earlier than you think, secure the tarp better than you think necessary, and don’t hesitate to ask for help.

Start earlier

Well, to be honest, I totally underestimated the time it took for me, an inexperienced non-craftswoman, to build a greenhouse of that size. Naturally, I sometimes had to reflect on how to proceed and all in all, I wasn’t very quick.

Additionally, you’re dependent on the weather. Heavy rains will stop your work on a project like that. That said, if I were to build a greenhouse again, I’d start earlier in the season. It was ready for planting by the end of May, and that was a bit too late for all my warmth-loving plants like tomatoes, cucumbers and peppers.

Use boards to secure the tarp.

Next, I’d fix the tarp on top with wood boards. That means, I’d first roll the tarp across the ceiling, place boards on top of it where the beams are and secure it all in place with screws. That way, the tarp couldn’t get torn out when the wind gusted in and lifted it.

Invest in better materials.

Also, four years in now, I’d definitely invest in a more weather-resistant tarp. The one I bought initially guaranteed weather-resistance for 3 – 5 years, and last year (after three years), I had to exchange the ceiling tarp. This may also have to do with the insufficient fixing to the beams just with screws, but it had also become brittle when I took it off. A better tarp is more expensive, of course, but it’ll be worth it in the long run.

Reconsider measurements

- For a greenhouse of this width, I learned that three instead of just two beds is better. They’re narrower, giving you better access to all plants.

- Plan the door width more carefully—mine could be 20 cm wider for easier wheelbarrow access through the growing season.

Ask for help

- Get help. I’m not good at asking for it, and I always want to know if I can do things on my own, but honestly, it wouldn’t have taken that long if I had asked the boys to help.

I only admit this to you. Hope none of my family will ever read this section… (Don’t tell them I said so!)

Resume

Four years later, my low-cost greenhouse alternative has weathered autumn storms that would have demolished those flimsy PVC tunnels I first considered. Inside, tomatoes climb past my head, peppers ripen in abundance, and I’ve extended my growing season by months. Every time I step inside—even just to check on seedlings on a February morning—I feel proud. Not because it’s perfect (it’s definitely not!), but because I built it with my own hands.

If you’re dreaming of your own greenhouse, I hope this guide shows you that building a greenhouse from scratch is possible. You don’t need to be a carpenter or engineer. You just need patience (a lot!), basic tools (some), and the willingness to learn as you go (absolutely!).

Start with that string frame, take it one step at a time, and before you know it, you’ll be harvesting tomatoes in your very own DIY greenhouse.

Happy building—and even happier gardening!

Want to know more about gardening? These posts are for you:

Beginner’s Guide: How to Start A Vegetable Garden

Easy Vegetables for Beginners: 11 Foolproof Crops for Your First Garden in 2025

Seed starting for beginners: A step-by-step guide for growing healthy seedlings

For an overview of all gardening articles, look here: Gardening – seasonalsimplelife.com